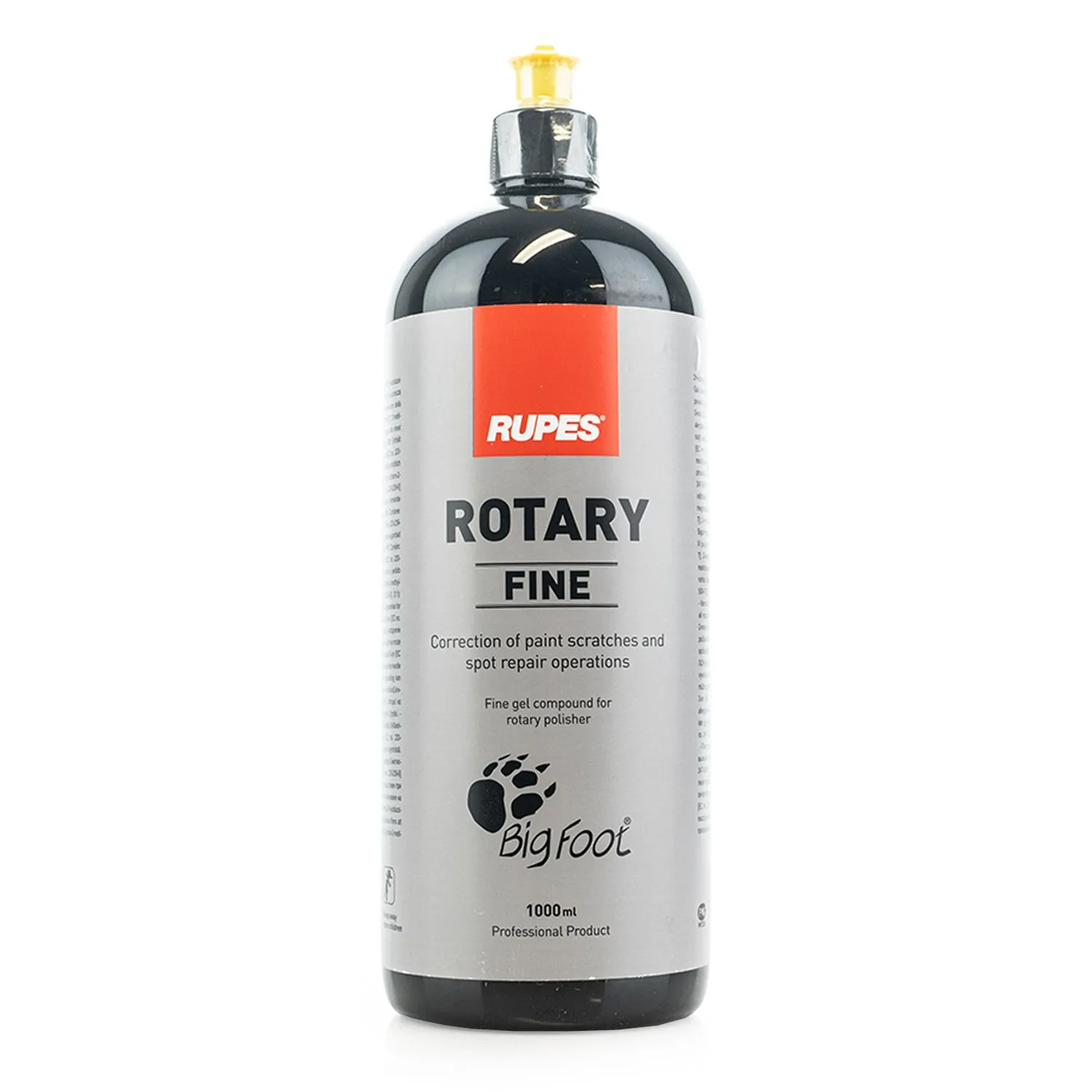

Unlock Polishing Perfection with the Rotary

Specifically crafted for the RUPES LH19E rotary polisher, the BigFoot polishing compounds offer unparalleled performance, ensuring maximum efficiency. Paint shop safe and suitable for any car paint, refinish, or OEM application, these compounds strike the perfect balance between fast cutting and achieving a flawless finish. The Fine Rotary compound, in particular, is formulated to deliver impeccable finishes on particularly hard clear coats.

Features:

🔧 Optimized for RUPES LH19E Rotary Polisher: Tailored to maximize efficiency when used with the RUPES LH19E rotary polisher, ensuring top-tier performance.

🚗 Universal Paint Compatibility: Suitable for any car paint, refinish, or OEM application, providing a versatile solution for various polishing needs.

⚙️ Perfect Mix of Fast Cutting and Good Finish: Achieve the ideal combination of fast cutting and a superior finish, elevating the overall polishing experience.

✨ Specifically Formulated for Hard Clear Coats: The Fine Rotary compound is uniquely formulated for perfect finishes on particularly hard clear coats, ensuring outstanding results.

🔄 Hologram-Free Final Step: Ideal for a hologram-free final step of spot repair, following the micro abrasive nib removal process, ensuring a flawless and pristine surface.

👌 Silicone-Free Formulation: BigFoot abrasive compounds are crafted without silicone, ensuring a clean and safe polishing process.

🔍 In-Depth Research and Quality Assurance: The compounds are the result of extensive studies and research, featuring high-quality abrasive mixes and a unique formula for the perfect combination of viscosity and aggressiveness.

🔄 Uniform Distribution on Polishing Pad: The unique compositions ensure consistent distribution on the polishing pad, optimizing the polishing process for superior results.

Directions:

1. Prepare Your Work Area: Ensure a well-ventilated, dust-free space for polishing.

2. Inspect the Paint Surface: Identify imperfections requiring correction.

3. Select the Fine Rotary Compound: Choose the optimal compound for initial polishing.

4. Equip the Rotary Polisher: Attach and install the compound on the rotary polisher.

5. Apply Compound to Polishing Pad: Use an appropriate amount on the pad.

6. Spread Compound on Surface: Ensure even application before turning on the polisher.

7. Polishing Process: Work compound into the surface with slow, overlapping motions.

8. Monitor Progress: Periodically inspect and adjust pressure for efficient correction.

9. Complete Polishing: Continue until desired correction and gloss are achieved.

10. Wipe Off Residue: Use a clean microfiber towel to remove any residue.

11. Inspect and Repeat if Necessary: Check for remaining imperfections and repeat if needed.

12. Final Inspection: Assess the treated area under different lighting conditions.

13. Store Compounds Properly: Seal the container tightly and store in a cool, dry place.